It can help to remove the contaminants entered from the outside very easily. Airlocks must be saved vacant, materials for example garments, shoes handles and so on. should not stored in the airlocks. I have noticed it often times in pharmaceuticals keeping these content in airlocks. In Pharmaceutical, Bio-Pharmaceutical and sterile production, the clean place environment is the most important prerequisite for all manufacturing activity: with out a good motion mechanism & background environment, no drugs might be developed for client usage. The intentions and objective are the reality of secure, reliant, and compliant Procedure inside a tightly controlled and monitored surroundings. Restricted User Demands or Design and style Philosophies should be published or inked down ahead of creating Airlocks in clear rooms. The challenge for virtually any High quality device will be to outline URS depending on regulatory considerations when the facility exports an item in different regulatory parts.

Enhanced Safety: Safety is paramount, and air locks contribute considerably to it. They involve personnel to wear the correct cleanroom attire prior to stepping right into a clean space, minimizing the chance of introducing outside the house contaminants. It’s a straightforward however effective way to copyright cleanliness expectations.

In summary, Airlock systems are the integral part and Employed in the different production processes to provide an efficient barrier to circumvent the contaminants and cross-contamination.

Significant-containment areas wherever worker defense is a precedence: Worker basic safety is paramount in environments containing poisonous or biohazardous elements, and sink airlocks aid guard workers by made up of airborne contaminants.

These airlocks here are designed with Sophisticated filtration systems and significant level of controls for making sure the integrity and sterility from the production procedure.

two.0 Bubble Airlock: These varieties of airlock obtaining greater excess weight inside the airlock and reduce pounds each outside. It can make an obstruction where by contaminants inside of both space pushed once more into their very own specific personal areas.

HEPA filtration systems are Utilized in sterile pharmaceutical manufacturing, biotechnology labs, medical center working rooms, and cleanrooms for industries like microelectronics, in which sustaining particle-free of charge air is critical for item quality and security.

As It's a general role that air moves from a region of larger click here pressure to the world of reduced stress.

Real-time checking and alarms may also help prevent important failures, alerting operators if tension differentials slide outdoors suitable restrictions.

If significant merchandise are likely in scope, the working height and width of All those items are exceedingly essential. Doorways must be adequately made to prevent any breaking down of partitions or doorways soon after design is finished. The full system requirements correct knowledge of Tools & equipments Utilized in the output and approach functions.

It makes a barrier exactly where contaminants in possibly place are pushed again into their own respective regions.

Endurance is essential in fermentation. Allow the vegetables to ferment for the suggested temperature for the specified period. This could range from a few days to numerous months, based on the recipe and your desired amount of fermentation.

In granulation home deliver ten Pa so when We'll open up the doorway, thoroughly clean air will move from airlock to granulation region and powders from granulation will never enter to airlock on account of differential strain. In the exact same way in corridor generate 10 Pa so when We're going to enter from corridor the cleanse air from air search will move into the corridor.

Skip to articles Pharmaceutical Updates was began to share know-how among the pharma pros & it will turn into handy to the pharma Specialists.

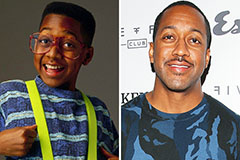

Jaleel White Then & Now!

Jaleel White Then & Now! Scott Baio Then & Now!

Scott Baio Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now!